The whole range from pigments to fertilizers, quartz to ore

Since decades, a wide variety of materials has been treated in our machines. Apart from the main materials, there are in fact quite a few others which are also important in the industries, for example, feldspar, quartz, ore, and sand. And in some cases we were approached by customers who wanted to prepare quite extraordinary materials.

Thanks to our technical know-how, not to forget the imagination and creativity of our engineers, we have always been able to supply solutions to all of these requirements provided the implementation with our machines seemed to be recommendable. Listening carefully and open-mindedly, doing comprehensive tests and analyses, developing concepts specifically adapted to the customers’ requirements, this is how we found ways to successfully solve the problem even when dealing with unconventional materials.

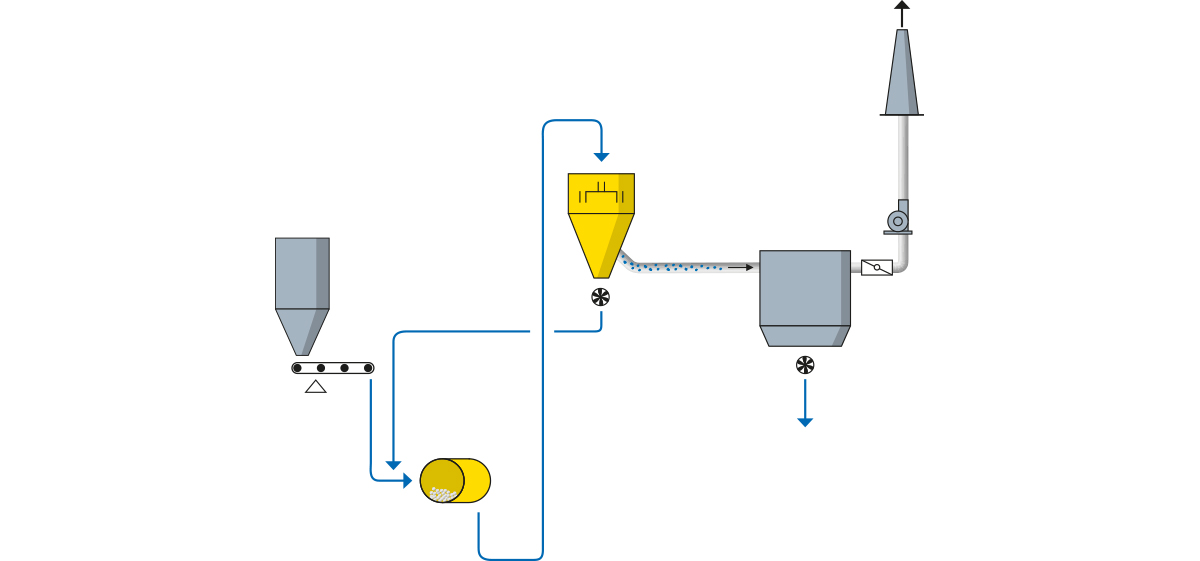

Grinding of hard materials

For fine grinding lumps of hard ceramic materials which are heavily abrasive, like quartz, feldspar, sintered magnesite, bauxite or fireclay, grinding circuits comprising ball mills and separators are provided. Instead of separators, screening machines are used in case of coarse grinding. The fineness of the products can be set within wide limits (0.01 to 5 mm). When the raw material moisture exceeds 2%, a Triplex dryer is installed ahead of the mill for predrying. The ground products are used in every sector of the ceramic industry. The raw materials, which are often not homogenous and due to their geological origin have different chemical and physical properties, are homogenized as a result of grinding.

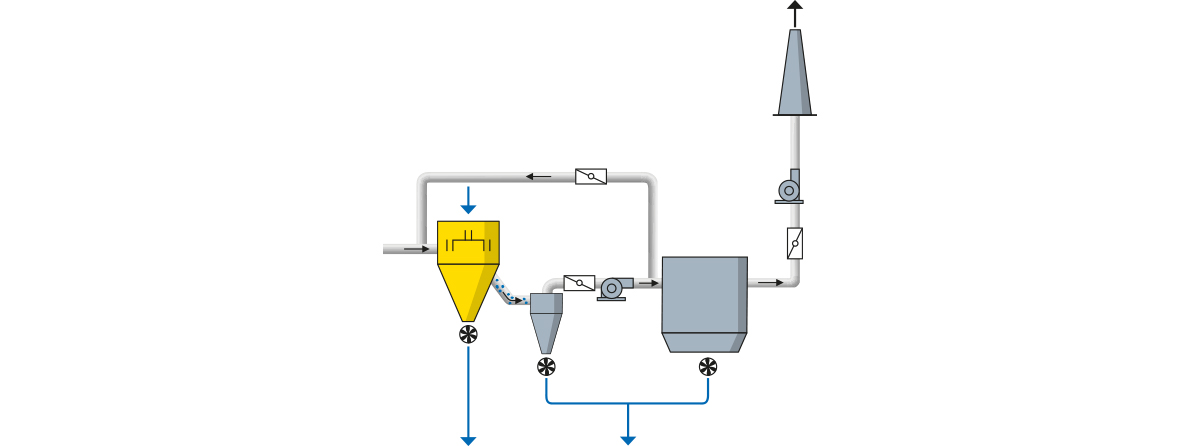

Separation with high-efficiency separators

The material to be separated is transported by the air flow to the separating zone where it is separated into fine and coarse materials. The latter is discharged through a cone for being conveyed to further process steps. The fine material is separated in a downstream cyclone or filter.

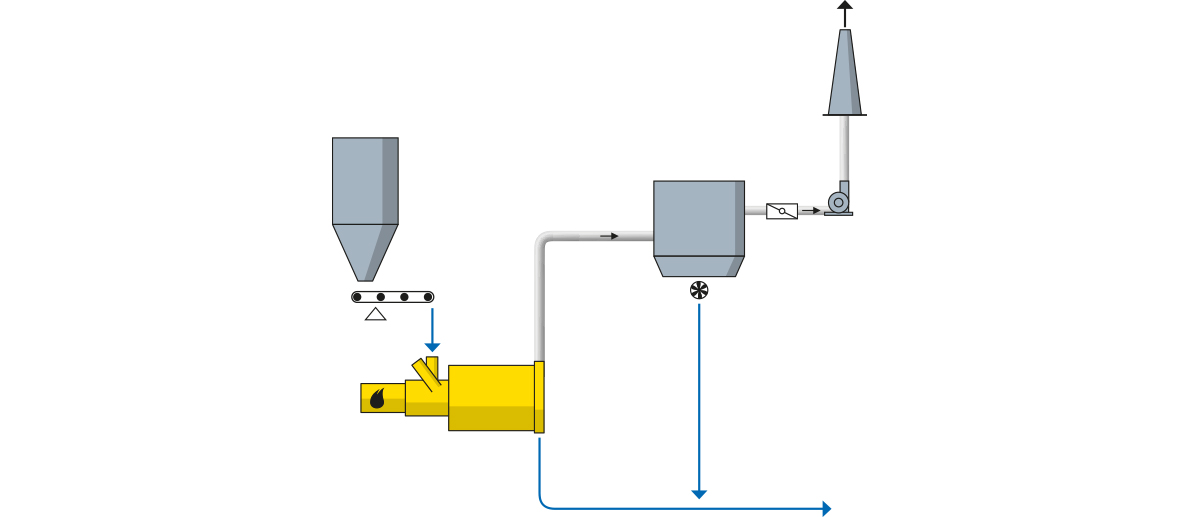

Drying

Lump-size ceramic raw materials like clay, kaolin, quartz, feldspar, etc. are dried in Pfeiffer Triplex dryers to the required residual moisture. The products obtained can be further processed in grinding plants, separated in classifying systems or used directly in plastic forming.

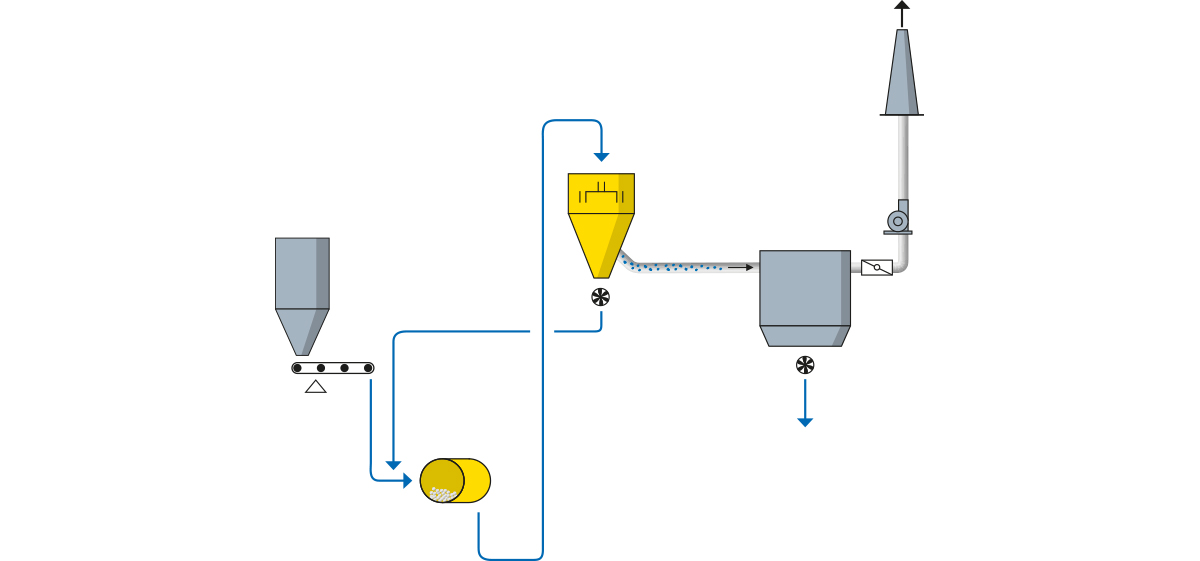

Grinding in the ball mill

For fine grinding hard materials, grinding circuits comprising ball mills and separators are provided. The latters are replaced with screening machines in case of coarse grinding. The fineness of the products can be set within wide limits (0.01 to 5 mm). The raw materials, which are often not homogenous and due to their geological origin have different chemical and physical properties, are homogenized as a result of grinding.