Our plants for quicklime preparation are operating all over the world

The history of our company is closely connected to the history of the lime industry. With our experience gained over decades, we have been in a position to constantly develop our grinding, separating, drying, and hydrating processes. Our large portfolio offers solutions representing the state of the art and particularly suited to your requirement. We can provide individual machines but we also conceive and build complete lime works plants from the kiln outlet to the packing station. These can be found in more than 50 countries.

Details on raw material

Calcium oxide (also called quicklime, burnt lime, or unslaked lime) is formed by burning limestone. Quicklime reacts with water, generating a great amount of heat. We distinguish soft-burnt lime, medium-burnt lime, and hard-burnt lime. In the construction industry, quicklime is added to mortar. It can also be used as a drying or neutralizing agent, as fertilizer lime and for the production of lime mortar and lime plaster.

By adding water, calcium oxide is transformed into calcium hydroxide (also called lime hydrate, hydrated lime or slaked lime). Lime hydrate can, for example, be used instead of limestone for flue gas desulfurization. To be noted that the amount of lime hydrate is smaller than that of limestone. Derived from quicklime, gypsum (calcium sulfate) has a whiteness of about 80% and is ready for other uses.

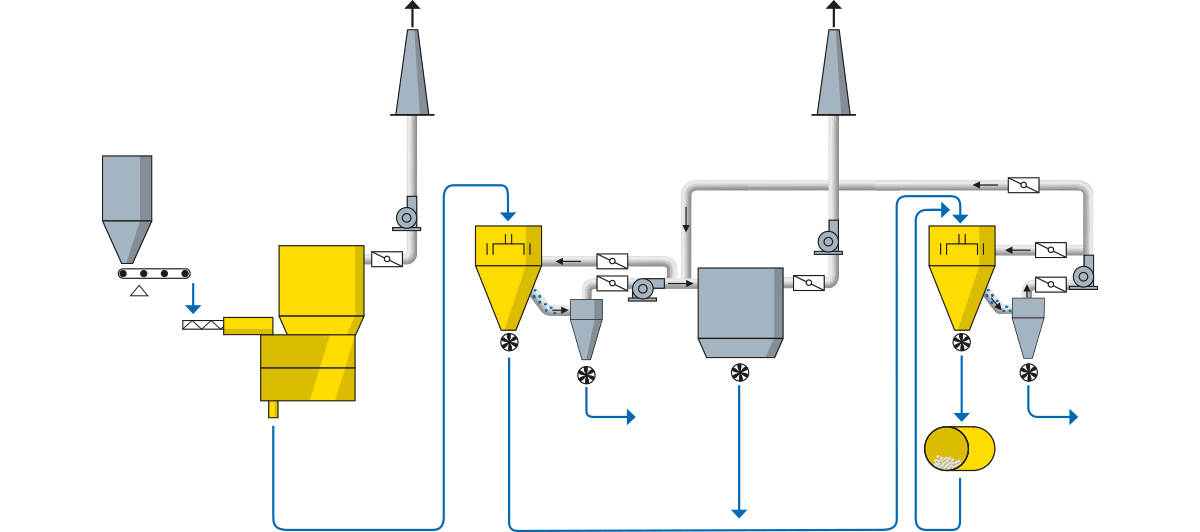

White fine lime and lime hydrate

Quicklime lumps are ground and classified in Pfeiffer MPS vertical roller mills. The fineness of the white fine limes can be set within wide limits (0.06 to 0.1 mm). In downstream Pfeiffer lime hydrators, water is added to quicklime, thus transforming it into lime hydrate. White fine lime is used for the production of limestone bricks and aerated concrete. Lime hydrate is used for the production of plaster and mortar.

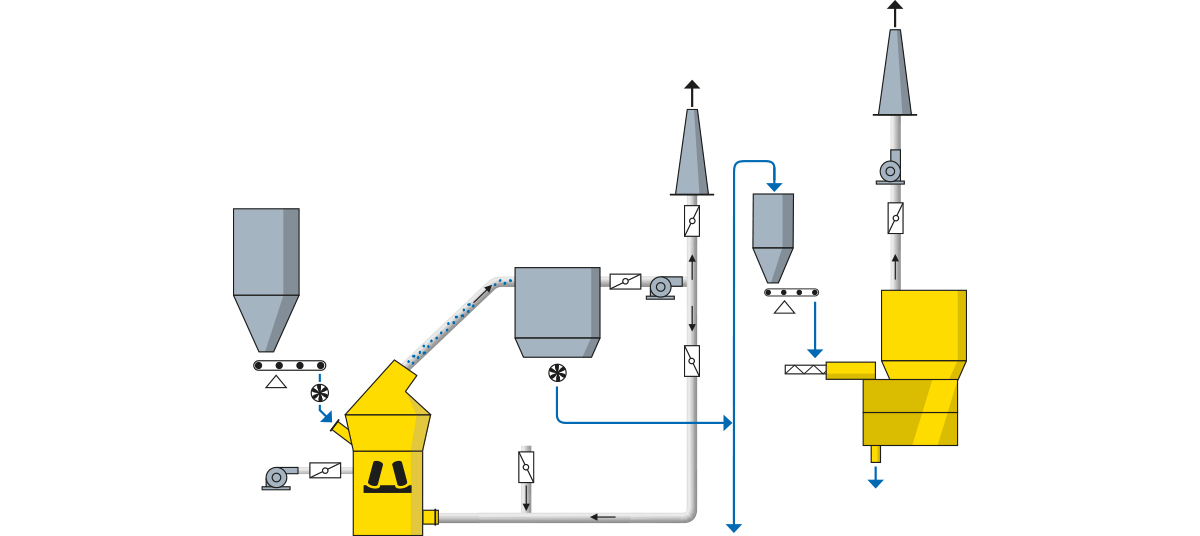

High-purity lime hydrate and building lime

In Pfeiffer lime hydrators, quicklime lumps are converted into lime hydrate by adding water. In downstream Pfeiffer separators, high-purity lime hydrate is separated from the grits. These are ground to target fineness in ball mills which operate in closed circuit with separators, thus producing building lime. High-purity lime hydrate is primarily used in the chemical industry and for water treatment.

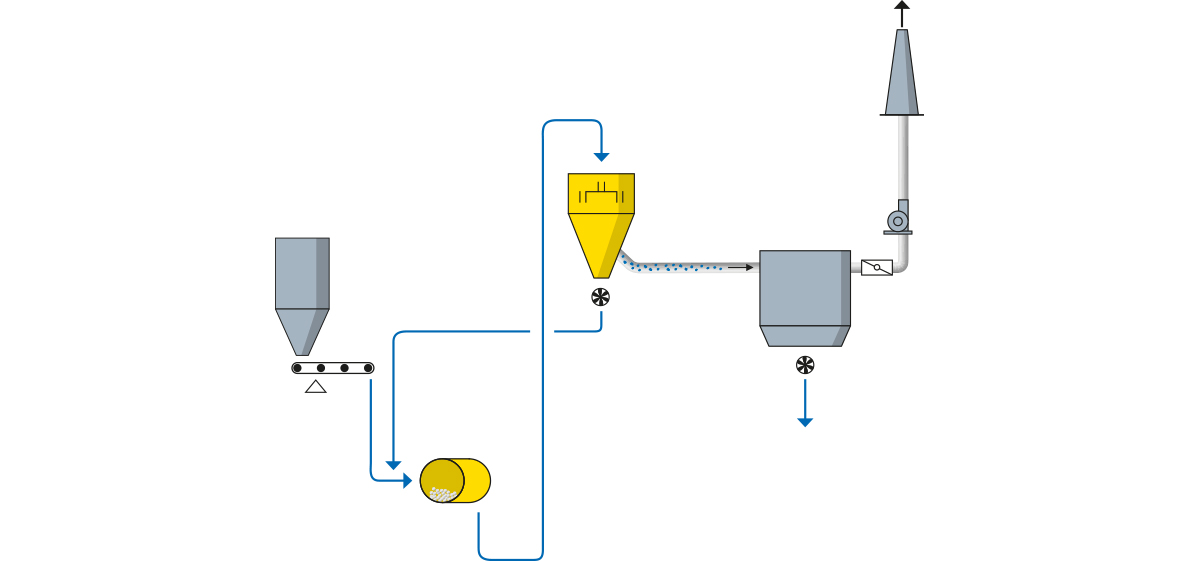

Grinding of lime hydrate in the ball mill

For fine grinding lime hydrate lumps, grinding circuits comprising ball mills and separators are provided. Instead of separators, screening machines are used in case of coarse grinding. The fineness of the products can be set within wide limits (0.01 to 5 mm). The ground products are used in every sector of the lime industry. The raw materials, which are often not homogenous and due to their geological origin have different chemical and physical properties, are homogenized as a result of grinding.