Maximum flexibility with Pfeiffer’s unique ready2grind

Pfeiffer’s modular mill solution enables flexible use in any place, bringing cement producers closer to their customers. This compact system is suited to producing all types of cement – perfect for local cement producers and market entrants as well as for large construction companies aiming to expand their position by manufacturing cement on the spot. The ingenious design allows the ready2grind plant to be transported and mounted fast and efficiently with manageable costs – making it the perfect concept to respond rapidly to the changing needs of the local cement markets.

The advantages at a glance:

- highest reliability, proven concept

- modules in standard container sizes for cost-efficient transportation

- rapid delivery, installation and commissioning

- highest operational availability with moderate investment

- immediate market entry, short amortization, reduced investment risk

- maximum flexibility, to react to changing market requirements at short notice

Features:

- cement of any desired type

- energy-efficient grinding system

- different plant sizes available

- compact modular design

- flexible feed system

- pre-assembled modules in standard container sizes

- perfect for small-scale production

- also available for other material such as limestone, gypsum, coal or similar

Proven mill technology for ambitious tasks

The design of the ready2grind system is based on the Pfeiffer vertical roller mill technology approved across the globe and on the decade-long experience in developing innovative mill technologies. The Pfeiffer vertical roller mill at the core of the ready2grind solution guarantees the highest level of operational reliability

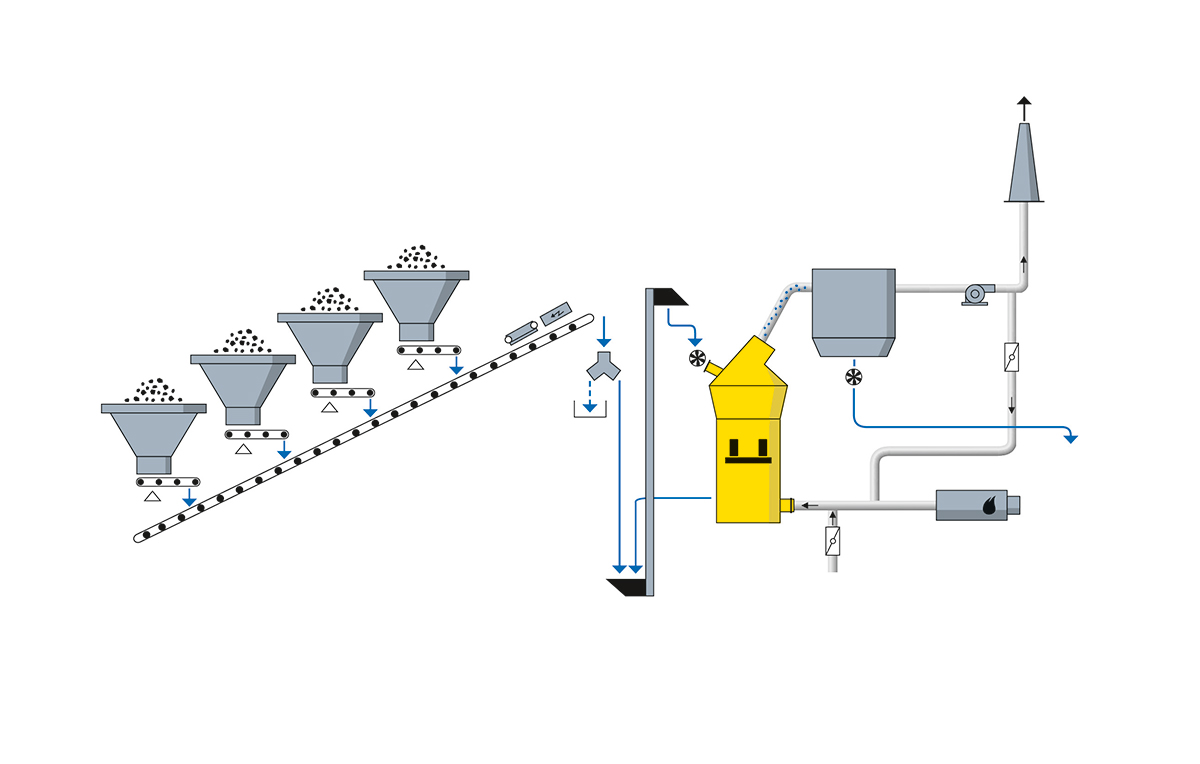

Grinding on the ready2grind system

The ready2grind system is extraordinarily compact. The modules in standard container sizes are delivered preassembled. The grinding process is the same as that of bigger Pfeiffer grinding plants. The above flow sheet shows the process of cement grinding as an example. Clinker and additives are ground, dried, and classified in the Pfeiffer vertical mill. Product quality and fineness can be set within wide limits (up to 6,000 cm2/g Blaine). The ground and dried product is separated from the process gas in a filter for entire dust collection which is followed by a fan. Downstream of the fan, the volume flow is divided: part of it is returned to the mill while the remainder is evacuated through the exhaust gas chimney.