Our separators – resulting from continuous development

They offer a wide variety of applications: for crushed limestone sand, limestone filler, white fine lime or lime hydrate. The features of the separators including optimum material distribution are convincing. Separator speed is variable allowing fine setting at the push of a button, even during operation. The Pfeiffer portfolio includes another type of separator which is similar in design but has no variable speed control: the SUT distribution table separator which is the smaller, less expensive version for applications where target fineness degrees stay more or less the same. No doubt Pfeiffer has everything you need in terms of separation. Our decade-long success is the proof!

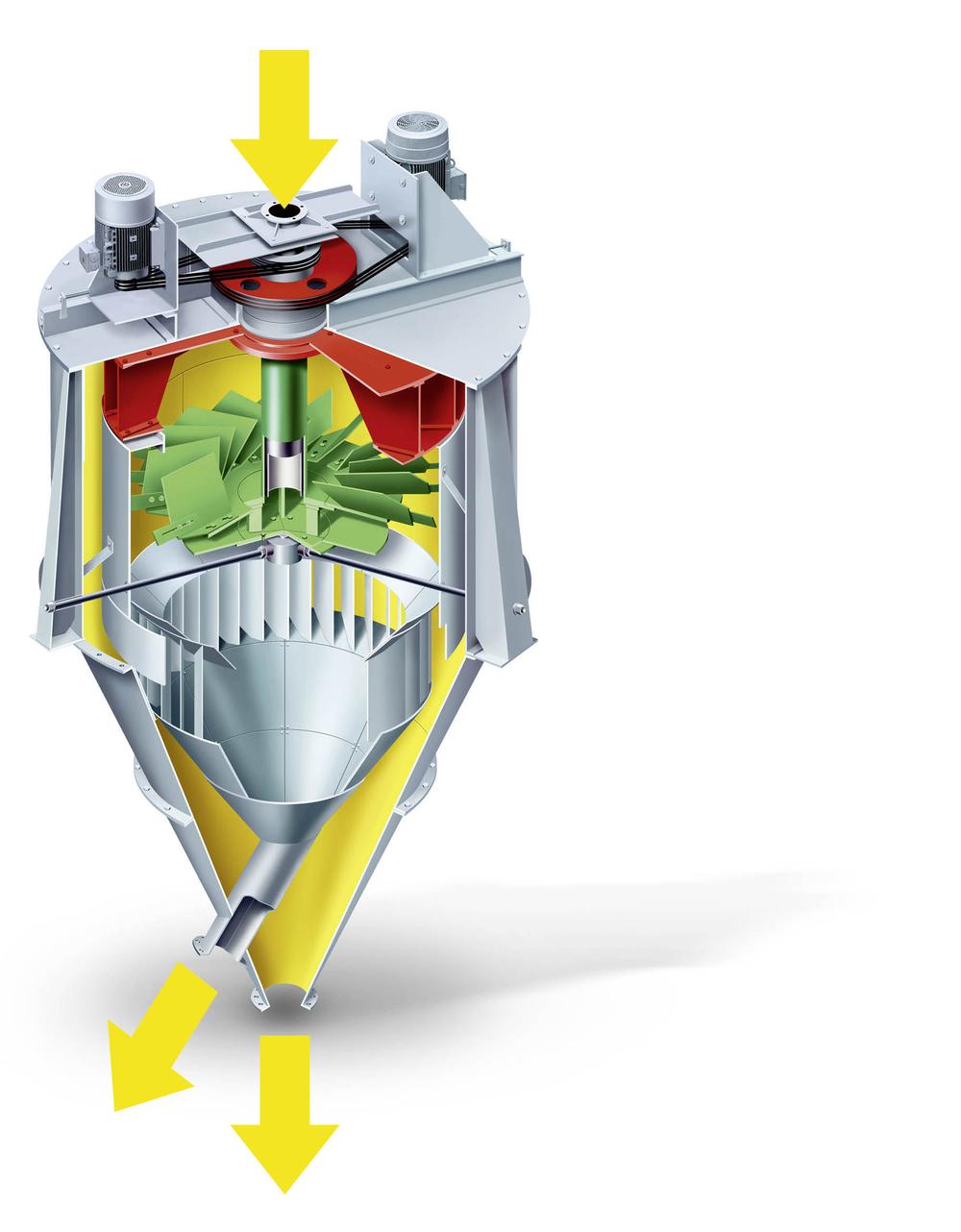

| FE | feed material |

| FI | fine material |

| C | coarse material |

| 1 | main fan for recirculating air |

| 2 | adjustable, variable-speed countervane system |

| 3 | distribution table with central material feed for optimum material distribution |

| 4 | louver for controlled return of recirculating air into separating zone |

Activate the markers for further information

Working principle

Spread within the air flow, the material to be separated is conveyed into the separating zone where it is separated into fine and coarse materials. The coarse material is evacuated through a cone for being directed to further processing steps. Unlike the high efficiency separators which have a downstream cyclone or filter for separating the fines from the air flow, the fine material in the SUV/SUT separators is discharged through a separate cone.

| Technical data | |

|---|---|

| Feed rate | up to 60 t/h |

| Feed moisture | dry |

| Target fineness degrees | up to 60 µm |

| Feed material | gypsum |

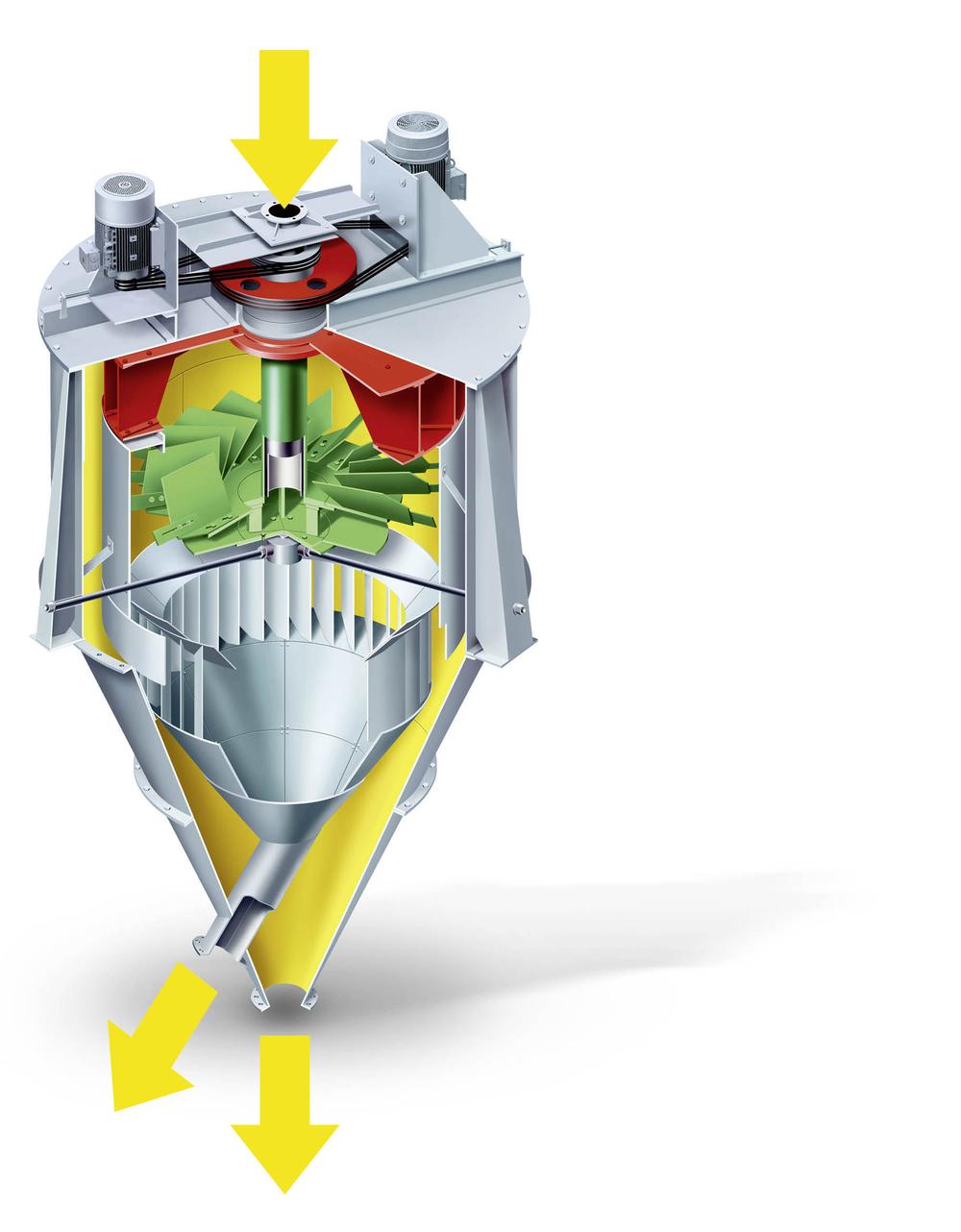

| FE | feed material |

| FI | fine material |

| C | coarse material |

| 1 | main fan for recirculating air |

| 2 | adjustable, variable-speed countervane system |

| 3 | distribution table with central material feed for optimum material distribution |

| 4 | louver for controlled return of recirculating air into separating zone |

Activate the markers for further information

Working principle

Spread within the air flow, the material to be separated is conveyed into the separating zone where it is separated into fine and coarse materials. The coarse material is evacuated through a cone for being directed to further processing steps. Unlike the high efficiency separators which have a downstream cyclone or filter for separating the fines from the air flow, the fine material in the SUV/SUT separators is discharged through a separate cone.

| Technical data | |

|---|---|

| Feed rate | up to 60 t/h |

| Feed moisture | dry |

| Target fineness degrees | up to 60 µm |

| Feed material | limestone |

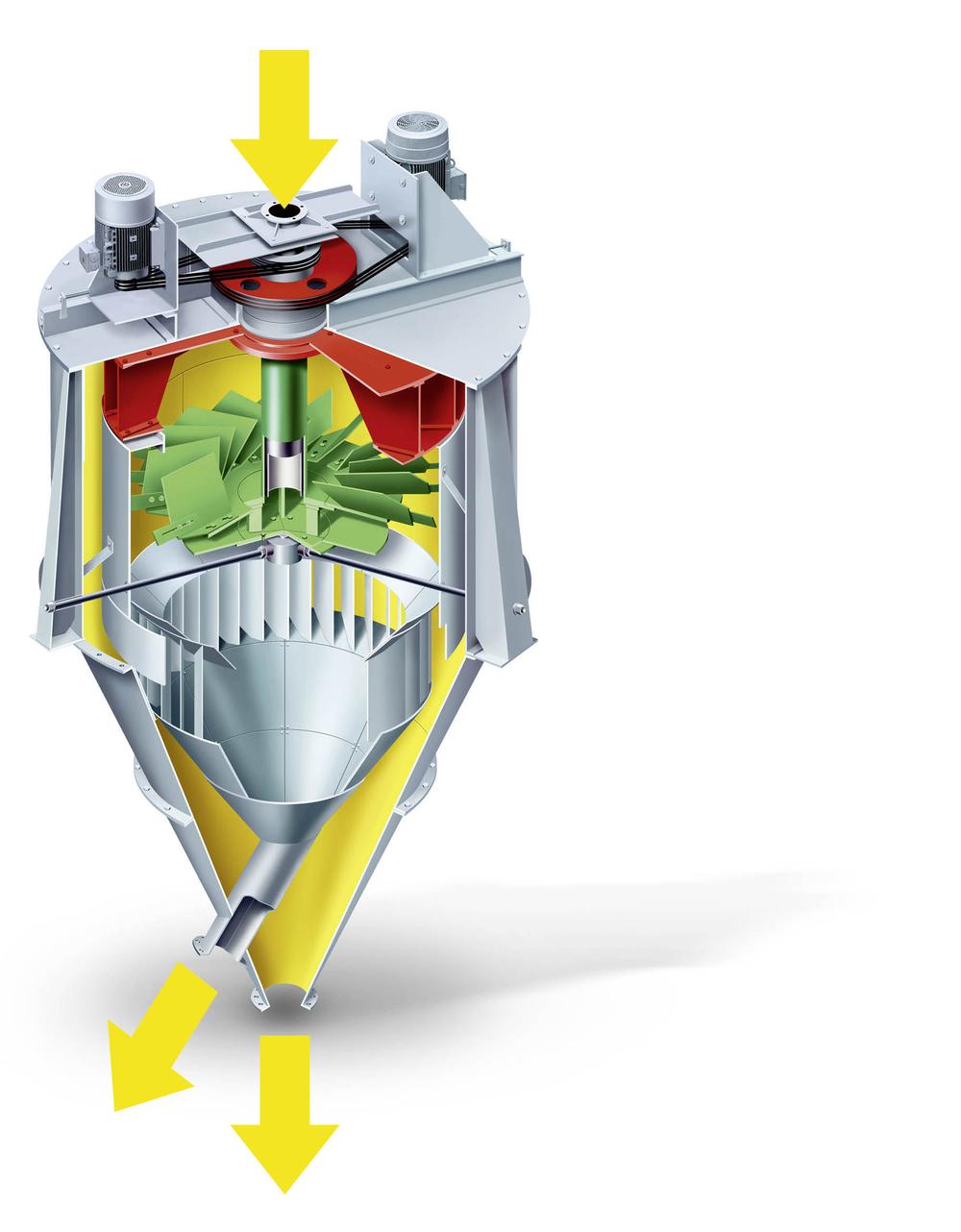

| FE | feed material |

| FI | fine material |

| C | coarse material |

| 1 | main fan for recirculating air |

| 2 | adjustable, variable-speed countervane system |

| 3 | distribution table with central material feed for optimum material distribution |

| 4 | louver for controlled return of recirculating air into separating zone |

Activate the markers for further information

Working principle

Spread within the air flow, the material to be separated is conveyed into the separating zone where it is separated into fine and coarse materials. The coarse material is evacuated through a cone for being directed to further processing steps. Unlike the high efficiency separators which have a downstream cyclone or filter for separating the fines from the air flow, the fine material in the SUV/SUT separators is discharged through a separate cone.

| Technical data | |

|---|---|

| Feed rate | up to 60 t/h |

| Feed moisture | dry |

| Target fineness degrees | up to 60 µm |

| Feed material | quicklime, lime hydrate |

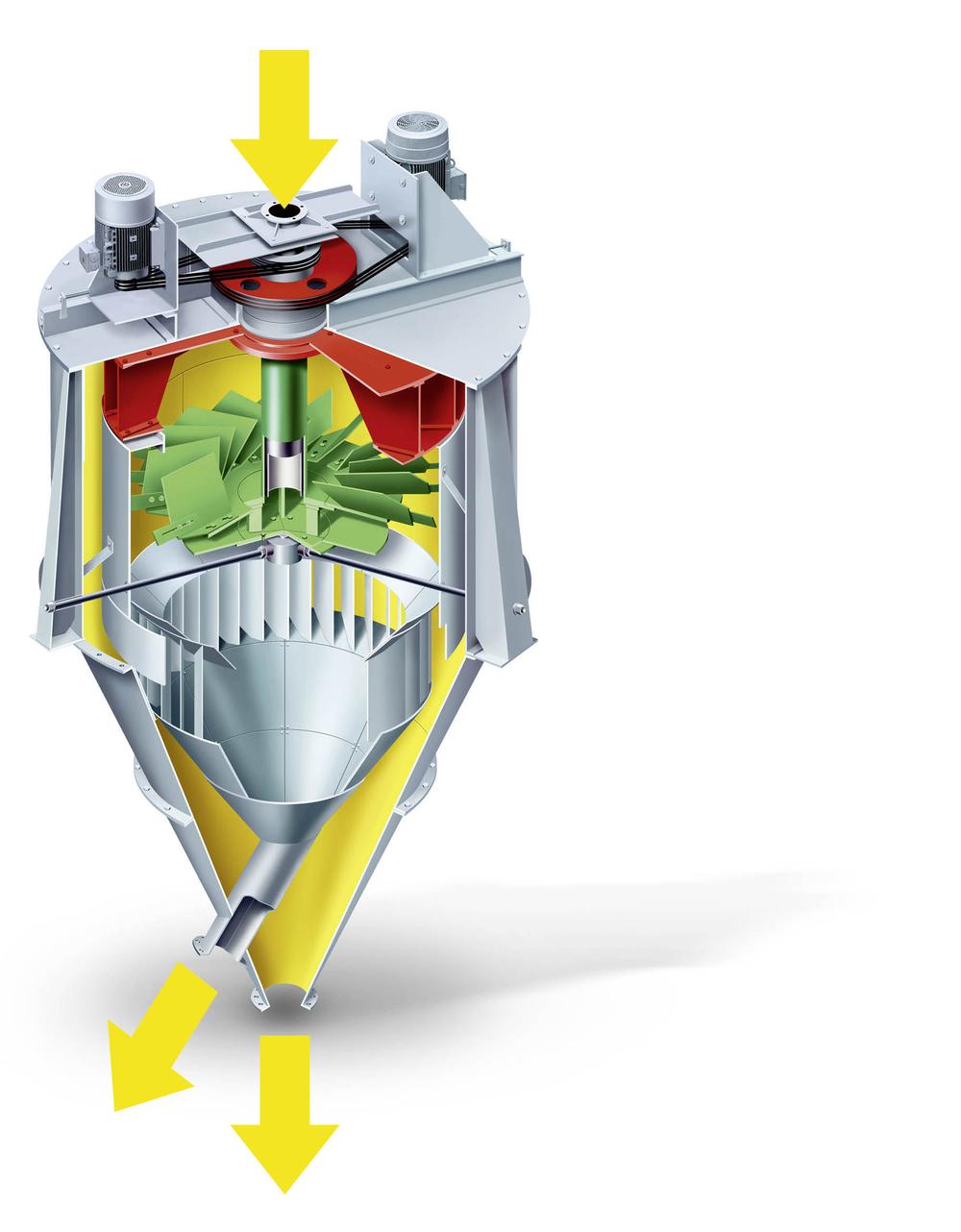

| FE | feed material |

| FI | fine material |

| C | coarse material |

| 1 | main fan for recirculating air |

| 2 | adjustable, variable-speed countervane system |

| 3 | distribution table with central material feed for optimum material distribution |

| 4 | louver for controlled return of recirculating air into separating zone |

Activate the markers for further information

Working principle

Spread within the air flow, the material to be separated is conveyed into the separating zone where it is separated into fine and coarse materials. The coarse material is evacuated through a cone for being directed to further processing steps. Unlike the high efficiency separators which have a downstream cyclone or filter for separating the fines from the air flow, the fine material in the SUV/SUT separators is discharged through a separate cone.

| Technical data | |

|---|---|

| Feed rate | up to 60 t/h |

| Feed moisture | dry |

| Target fineness degrees | up to 60 µm |

| Feed material | quartz, talc, barite, feldspar, dolomite, broken glass bottles, sintered magnesite, de-icing salt, serpentine, corundum, etc. |