Capacity increase at Barroso – significant reduction of total cost per ton of cement

LafargeHolcim, one of the global players in the cement industry, had decided to increase its production capacities in Latin America, more precisely in the existing cement works in Barroso, Brazil. This decision was taken in consideration of its strategic location between Belo Horizonte and Rio de Janeiro in the state of Minas Gerais, in the south-eastern part and most important market of Brazil.

Basing on the assessment that Brazil would remain a challenging market in the years to come, LafargeHolcim aimed at creating a new line at Barroso with an ultramodern plant and the best mill technology available worldwide. The total capacity of the plant should be more than 3 million tons of cement per year so that 450 tons would have to be ground in one hour.

LafargeHolcim was aware of the fact that for producing profitably on the Brazilian market, the cost per ton of cement produced would have to be reduced, with a simultaneous increase of quality and efficiency. At a very early stage of the project, the group recognized the advantages of the one-mill solution in terms of low capital expenditure, for example.

Project phase and requirements

With his complex requirements, the customer had set the bar very high for the mill supplier: reduction of production cost, increase of efficiency, maximum throughput rates, production of different mixed cements, and all that with a relatively low capital expenditure. Moreover, the customer aimed at the highest possible plant availability and sophisticated maintenance concepts in order to keep the cost per ton of cement produced at a permanently low level.

It turned out rapidly that the only adequate solution to this challenge was a vertical mill to be installed at the core of the cement grinding plant. To keep capital expenditure as low as possible, LafargeHolcim favored the option of producing 450 tph on just one mill. But for this a total drive power of 11,500 kW was necessary which was, however, not achieved with usual vertical mill drives.

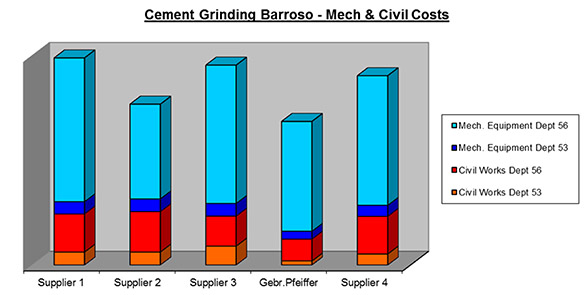

A thorough comparison of the available mill technologies revealed that Gebr. Pfeiffer was the only mill supplier to meet all requirements by offering a suitable and sustainable solution and, what is more, at the lowest CAPEX as compared with other suppliers.

As a result, the mill manufacturer from Kaiserslautern/Germany was awarded the contract for supplying the most modern and biggest cement mill in the world. The Pfeiffer mill of the type MVR 6700 C-6 with its optimum dimensioning for the production of 450 tph of cement is suitable for grinding various mixed cements containing clinker at rates of up to 90% and slag of up to 65% down to product fineness degrees of 4,000 to 4,800 cm² Blaine. The drive of the mill – the so-called MultiDrive® - was conceived in a joint project by Gebr. Pfeiffer and Siemens-Flender simultaneously with the development of the MVR mill so that both units could be optimally adapted to each other. With the MultiDrive®, the required drive power of 11,500 kW was made possible in the first place. It has proven successful in industrial operation since 2008 and was fitted with frequency converters to drive the Barroso mill in order to adapt the mill speed to the various product qualities.

The combination MVR mill/MultiDrive® has revolutionized the vertical mill technology not only with its high drive power but also thanks to additional unique features such as six grinding rollers and six drive modules each of which can be taken out of the system separately for maintenance purposes while operation is going on with at least 84% of nominal grinding capacity. Such a high rate of plant availability – unequaled so far – was another criterion in the customer’s decision for the MVR mill. In fact, with the two-mill concept considered as an alternative, the customer would have had to accept a significantly increased capital expenditure and a 50% drop of grinding capacity during a downtime of one of the two mills, with no active redundancy of rollers and drives, unlike on the MVR mill and MultiDrive®.

Project data

- Customer: LafargeHolcim Brazil

- Project: Barroso, Brazil

- Plant/Machines: Biggest cement grinding plant in the world with vertical mill MVR 6700 C-6 and MultiDrive®

- Material to be ground: slag cement

- Throughput rate: 450 tph

- Fineness: 4,300 cm²/g (Blaine)

Results and benefits

The mill has been producing to the full satisfaction of LafargeHolcim since April 2016.

In his lecture he gave in Fort Lauderdale in December 2016, Juliano Menezes de Melo (Barroso Plant Manager) confirmed the extraordinarily smooth run of the MVR mill. Moreover, he was impressed by the high flexibility of the plant, allowing the production of cement qualities which initially had not been planned. In addition, the commissioning of the plant had been carried out very satisfactorily as he stated in his lecture.

According to another publication of LafargeHolcim, it was possible, within the period from 2014 to the beginning of 2017, to reduce total cost per ton of cement produced by about 25% with the new line and its Pfeiffer MVR mill.

Thanks to the active redundancy of mill and MultiDrive®, a high rate of availability unequaled so far has been made possible even on the biggest mills and drives. So highest availability plus lowest CAPEX make us – Gebr. Pfeiffer – the most innovative supplier to turn to when it comes to setting up big cement plants with the proven one-mill solution, both for raw meal and cement grinding.